By Frederick d’Oleire Uquillas, Science Communications Fellow for the AI Lab

Start with a flat sheet of metal. Not much to look at, really. Maybe a little glare from the overhead lights, maybe the smell of laser-cut steel or brushed aluminum if you lean in close. But then, introduce a few cuts, some elegant decisions, and a gentle twist. The sheet breathes, arches, flexes, and suddenly you’re no longer looking at a blank surface. You’re looking at a structure. This is kirigami.

And, in the age of AI, the ancient craft is being reborn as a physics playground.

Kirigami, the lesser-known cousin of origami, is the Japanese art of paper cutting. The word itself comes from “kiri” meaning “cut,” and “gami” meaning “paper.” Unlike origami, which focuses on folding, kirigami involves strategic cuts that allow sheets to stretch, twist, and morph into surprising three-dimensional forms. Kirigami may once have lived in craft books and quiet afternoons, but today, it’s become a gateway into architected materials, engineered materials where the desired properties are achieved by controlling the geometric arrangement of structural elements, rather than solely relying on the material’s inherent properties. Think of an egg carton: The cardboard itself is flimsy, but the shape? Strong enough to cradle breakfast or brace for impact. Now imagine that idea applied to steel, polymers, or carbon composites, supercharge it with machine learning, and you unlock a universe of architected lattices with extraordinary properties.

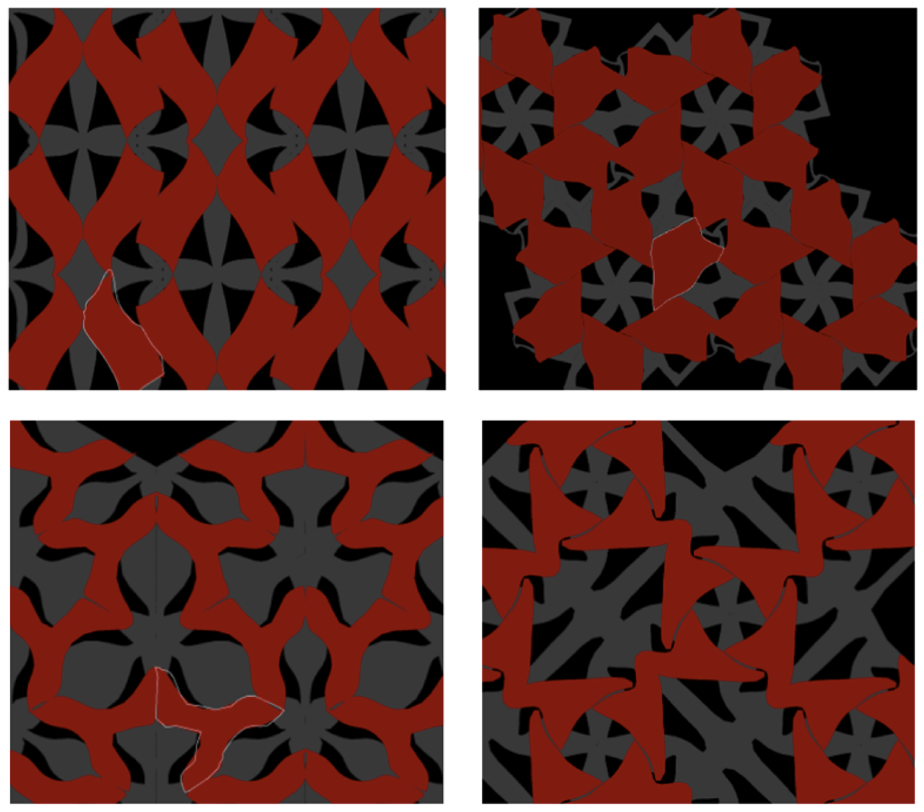

What graduate student Isabel Moreira de Oliveira at the Form Finding Lab and her collaborators at the Laboratory for Intelligent Probabilistic Systems at Princeton University are exploring isn’t your classic stretch-a-sheet-with-slits style. With this project, now on display at the European Cultural Centre’s Biennial Architecture Exhibition in Venice, they are building on an existing rotational kirigami system and pushing it into new territory. By applying AI-driven design tools, they are expanding the accessible design space, uncovering patterns and mechanical behaviors that would have been extremely challenging to identify through manual exploration alone. Specifically, the researchers are working with spin valence kirigami, a system originally introduced by academic collaborator Emily Baker at the University of Arkansas. It’s a kind of geometric ballet where arrays of rigid tiles (hexagons, triangles, squares, and other shapes) are connected at nodes and pivot like tiny, hinged dancers. The mechanics are subtle, but profound. Instead of linear expansion, these systems deploy through coordinated rotations, transforming flat surfaces into curved, load-bearing, often mesmerizing structures.

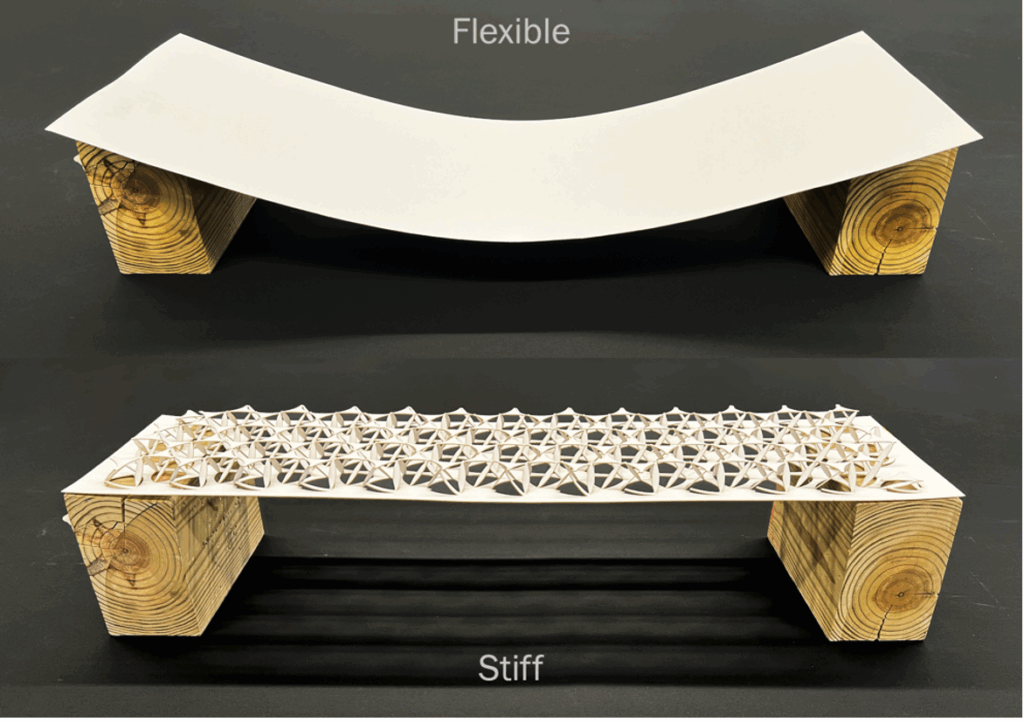

At the heart of it all lies a beautiful physics problem: How do you engineer stiffness and flexibility into the same system, using nothing but geometry? That’s not a trick question. The answer is, you encode mechanical behavior directly into the form, tuning the rotational degrees of freedom, the hinge lengths, and the angular stiffness of connections. Small changes to cut geometry can shift the system from compliant and squishy to stiff and structural. A few millimeters here or a degree there, and suddenly your structure doesn’t just stand, but it stands strong.

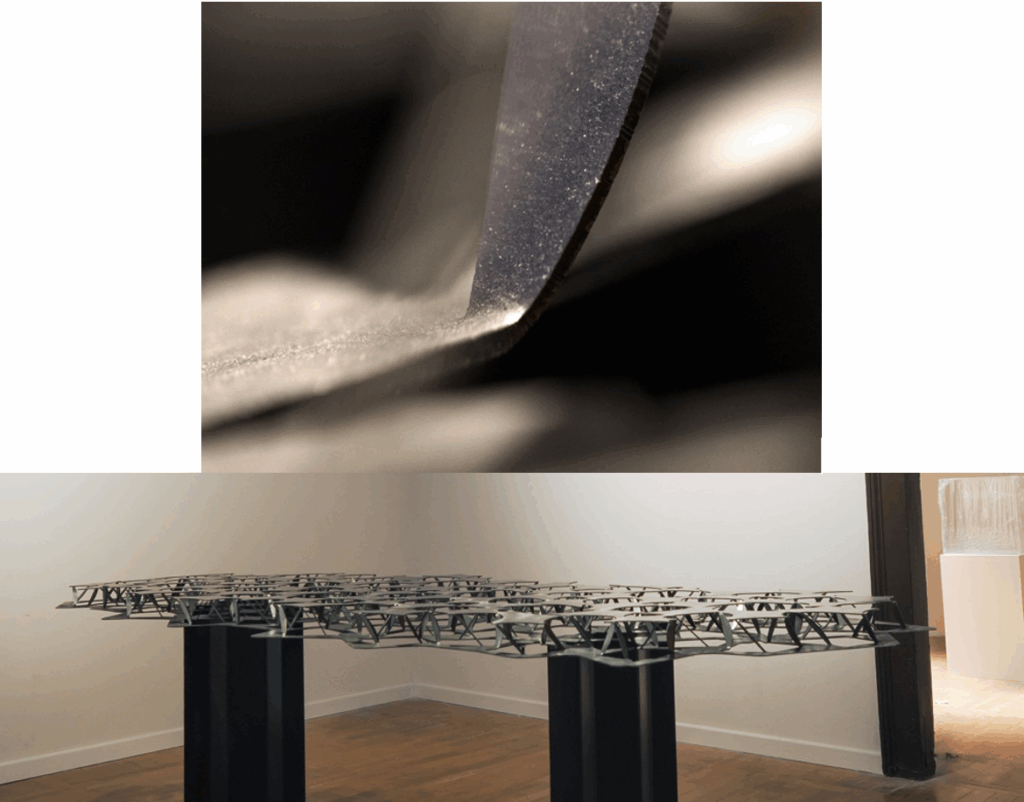

These rotational mechanisms obey nonlinear laws of deformation. The magic lies in how each kirigami unit cell connects to its neighbors, creating a network where movement in one part ripples through the whole – much like the collective action in a space frame. Rather than behaving as isolated elements, the units coordinate their rotations so the structure can transition from a flat sheet to a three-dimensional, load-bearing form. The result is a material that ships flat for efficiency yet deploys into something structurally robust and architecturally striking.

But navigating this design space by hand is…well, let’s say adventurous. There are millions of possible tile arrangements, cut angles, hinge types, and boundary constraints. That’s where AI sweeps in like a tireless but patient design partner.

Using machine learning tools, the lab is working toward training its AI to understand the relationship between cut geometry and mechanical output. Feed it a dataset of simulations: stretch a pattern, twist it, compress it, record how it responds. Over time, the AI learns to predict behavior without running the full physics each time. But more excitingly, it learns to design backward – to start from a desired behavior, say, “withstand 50 kg (110 lbs.) of concentrated load over a 4-meter span,” and output the geometry that can make that behavior real.

This is called inverse design, a powerful tool for inventing architected structures at the meter scale. Traditionally, engineers build from the bottom up: define the material, then simulate the structure. But with inverse design, you start with the dream and let the AI trace the blueprint back from performance to a pattern.

In de Oliveira’s work, these AI-guided patterns are then put through rigorous finite element analysis. This isn’t guesswork, though. The models capture bending stiffness, torsion, local buckling, and real-world constraints like fabrication tolerances. They’re not just playing with paper. They are engineering steel, and expanding the design space of spin valence kirigami towards applications across scales.

The results are stunning. One of the Form Finding Lab’s experimental systems, based on rotating square motifs, expands outward with a delightful flourish, holding shape with surprising strength. Others use hexagonal or diamond tiles to direct force flow and prevent local collapse. The behavior isn’t just binary (floppy vs. stiff), but tunable, and often anisotropic, meaning different directions can have different stiffnesses. A structure might yield vertically during deployment but remain rigid after its reconfiguration. This is mechanical intelligence, built into sensors or motors, but into the shape of the matter itself.

For a bit of context, it’s worth noting the broader movement. In a recent PNAS study, also coming out Princeton University, the laboratory of Prof. Paulino demonstrated a folded kirigami sheet that could transition between polarized and non-polarized mechanical phases, using cuts and folds to toggle the underlying topology of force propagation.

That work leans toward the topological frontier – playing with mechanical band gaps and symmetry-breaking. It’s brilliant, but a bit more esoteric.

As part of this broader movement, de Oliveira’s approach extends the tangible, the deployable, the beautiful: pavilions that unpack themselves, temporary shelters that ship flat and rise up rigid, facades that adjust with the weather. The physics here is grounded in real-world constraints, but also elevated by architectural imagination.

Picture this: You ask the AI for a four-meter span. “Sure,” it replies, “but where can I put supports? What’s the max deflection you’ll allow? Any aesthetic preferences? A little twist here? A spiral there?” You answer, and moments later, it hands you a tile pattern, a set of rotational joints, and a promise: Cut here, connect there, fold once, and your structure will do exactly what you asked.

It’s not magic. It’s mechanics.

So, what do we call this unfolding collaboration between ancient craft and modern code? Between pattern and performance? Between whimsy and stiffness? You might just call it the future of structure.

And it all begins with a flat sheet, a curious mind, and a few very intelligent cuts.

Curious to learn more? You can find more on de Oliveira’s and her team’s work here, here, and at kirigami-strata.ai.

Leave a Reply